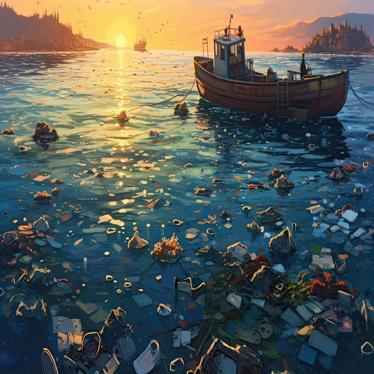

The sea is a living space for yacht owners and crew. Clean blue waters are vital for the sustainability of this lifestyle. Waste management on yachts goes beyond aesthetics. It relies on strict international rules and environmental responsibilities. The operational success of a modern yacht relates directly to how effectively waste is processed and stored. Industrial partners like UNOKS shape the technical infrastructure in these processes. Correct system installation prevents marine pollution and ensures a comfortable cruising experience.

Classification of Waste Types in Maritime

Waste generated on yachts differs from land-based facilities. System engineers categorize waste based on its source and chemical structure. This distinction determines the disposal method.

Grey Water and Black Water Distinction

Liquid waste falls into two main categories. Black water comes from toilets and contains pathogens. Grey water originates from showers, sinks, laundry, and galley drains. Black water cannot be discharged directly into the sea. It requires collection in special tanks or processing through biological treatment units. Grey water contains chemicals, so some regions treat it the same as black water. The flow rate of these two streams is the deciding factor in calculating tank capacities.

Solid and Galley Waste

Yacht galleys operate at industrial kitchen standards. Food preparation creates organic waste, packaging materials, glass, and metal waste. Organic waste must be processed quickly to prevent odors and bacteria. Plastic and hazardous waste (batteries, oil filters, etc.) must be stored onboard and delivered to port facilities.

MARPOL 73/78 and the Legal Framework

The International Maritime Organization (IMO) enforces the MARPOL convention to prevent marine pollution. Waste management systems on yachts must fully comply with MARPOL Annex IV (Sewage) and Annex V (Garbage).

These rules regulate discharge permissions based on the vessel's distance from the shore. The table below summarizes the basic restrictions:

Table 1: Discharge Rules and Processing Requirements by Waste Type

| Waste Type | Distance from Shore (Miles) | Processing Requirement | Discharge Permission |

| Plastics | Prohibited Everywhere | Storage and Land Delivery | Strictly Prohibited |

| Ground Food | > 3 Nautical Miles | < 25mm particle size | Permitted (While en route) |

| Unground Food | > 12 Nautical Miles | No processing | Permitted (While en route) |

| Black Water (Treated) | > 3 Nautical Miles | Certified treatment unit | Permitted |

| Black Water (Raw) | > 12 Nautical Miles | Holding tank | Permitted (At specific speed) |

| Floating Materials | Prohibited Everywhere | Compaction/Packing | Prohibited |

Note: Rules are much stricter in designated "Special Areas" (Mediterranean, Baltic Sea, etc.). Discharge may be completely prohibited in these regions.

Waste Processing Technologies Used on Yachts

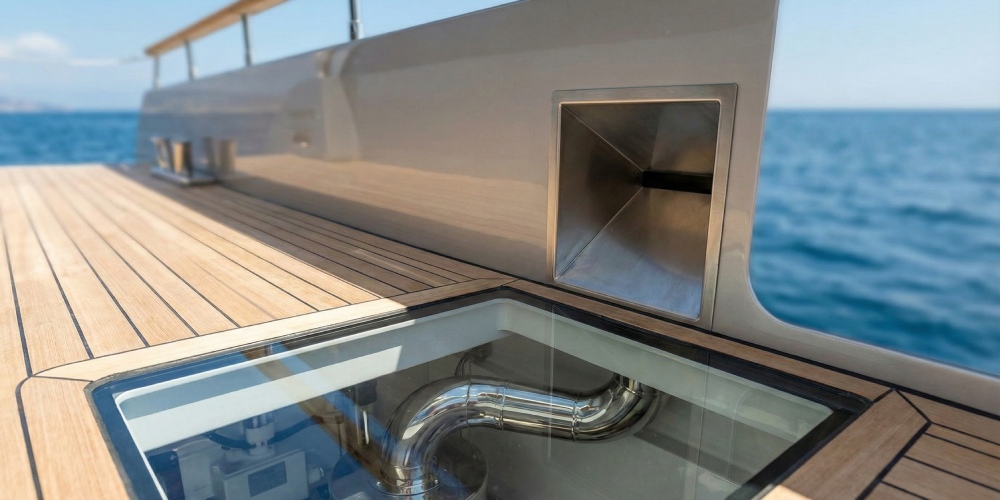

Limited space and high hygiene expectations make compact and efficient equipment essential on yachts. Industrial kitchen and waste system manufacturers develop specific solutions for this need.

Waste Disposers

Industrial waste disposers are critical equipment in galley operations. These units, mounted under the sink, turn food scraps (vegetable peels, small bones, etc.) into liquid form in seconds. This process reduces waste volume and prevents bad odors. Disposers meeting UNOKS standards prevent clogging with high-torque motors and stainless steel blades. Ground waste can be sent to the grey water tank or directly to the sea (within legal limits).

Waste Compactors

Storage space is valuable during long cruises. Waste compactors reduce the volume of plastic, paper, and metal packaging by up to 80%. These machines work with hydraulic press logic and turn waste into cubes or bales. This saves space in the waste room and provides hygienic storage until the port.

Biological Treatment Systems

Large yachts have treatment plants to render wastewater harmless to the sea. These systems use bacterial decomposition, chlorination, or UV filtration methods. The system cleans the water to a level that meets international standards. Treated water can be reused as technical water or safely released into the sea.

How to Create an Effective Waste Management Plan?

The management process is as important as the technical hardware. Yacht owners and captains establish a flawless system by following these steps.

- Equipment Selection: Tanks and processing devices must match the yacht's size, passenger capacity, and cruise duration. Durable materials like stainless steel are preferable.

- Crew Training: Personnel must know which waste goes into which unit. Incorrect usage (e.g., throwing wet wipes into the toilet) clogs treatment systems and causes major breakdowns.

- Maintenance Periods: Pumps, grinders, and filters require regular checks. Professional maintenance before and after the season extends the system's life.

- Record Keeping: The Garbage Record Book is the official document recording all waste operations (discharge, incineration, delivery). Authorities examine these records during inspections.

Sustainability and Future Trends

The maritime sector is moving toward a "zero waste" goal. New generation yachts use systems that convert waste heat into energy and fully recyclable materials. Biodegradable cleaning supplies and micro-plastic filters are becoming standard. Environmentally conscious yacht owners determine the direction of the market by demanding these technologies.

Waste management on yachts is a sign of respect for the seas, beyond technical necessity. Clean seas are possible with correct planning, quality equipment usage (disposers, presses, treatment units), and conscious personnel. UNOKS continues to offer professional solutions to the maritime sector's needs in this area with its industrial experience. Protecting the marine ecosystem guarantees the future of yachting.